Precision Machining

PRECISION MACHINING

Kadon Precision Machining can produce the part you want, when you need it – Regardless of complexity – We get it done! Our state-of-the-art facilities are configured for prototypes to million part+ runs and everything in between. When you need precision parts delivered on time at a fair price, call 815-874-5850.

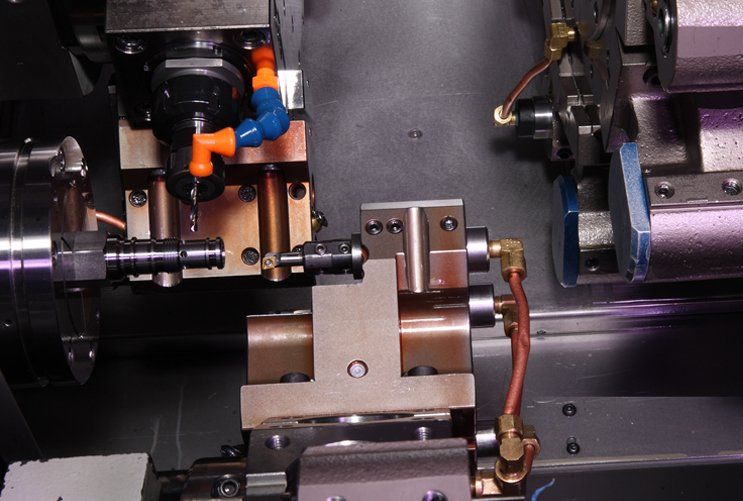

SWISS MACHINING

Swiss Machining includes processes such as drilling, boring, turning, milling, and knurling along with special processes such as deep hole drilling, hobbing, broaching, threading, and slotting without multiple setups.

Diameters up to 32MM(1.259). Tolerances of ±0.0001″.

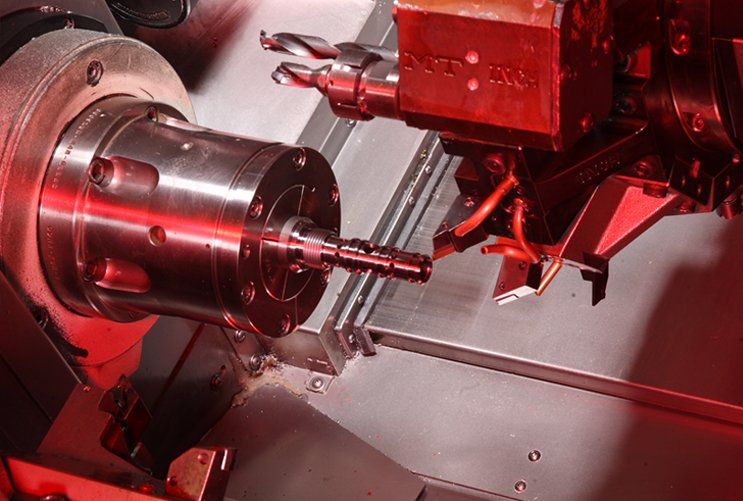

MULTI-AXIS MACHINING

Multi-axis machining allows multiple tools to cut multiple pieces of material simultaneously. The total number of operations needed to complete a part is divided among the number of spindles, making for a very efficient process.

Diameters up to 72MM(2.834). Tolerances of ±0.0001″.

CNC MACHINING

Multi-axis machines with pallet fixturing and CNC control can precisely carry out processes such as drilling, boring, milling, contouring, and counter-boring, while maintaining very tight tolerances. CNC Vertical Machines enable multiple features to be machined simultaneously.

Diameters up to 457.2MM(18). Tolerances of ±0.0001″.

MILLING & ROBOT MILLING

Milling machines are designed to machine metal. Often automated, milling machines can be positioned in either vertical or horizontal orientation to carve out materials based on a

pre-existing design. These designs are often CAD directed, and many milling machines are CNC-operated, although manually and traditionally-automated milling devices are also common. Milling machines are capable of dynamic movement, both of the tool and the workpiece, and many milling machines can perform multi-axis machining.

pre-existing design. These designs are often CAD directed, and many milling machines are CNC-operated, although manually and traditionally-automated milling devices are also common. Milling machines are capable of dynamic movement, both of the tool and the workpiece, and many milling machines can perform multi-axis machining.

SPECIAL MANUFACTURING SYSTEMS

– In order to meet specific and unique customer requirements, Kadon Precision Machining offers value-add manufacturing systems and processes: Hand assembly (O-ring, threading mating parts, slip fits, etc.), press fit, laser marking, brazing, coining, crimping, saw cutting, welding, and more.

Kadon Precision Machining is a partner you can depend on to consistently deliver high quality precision machined parts on time, and at a fair price – Throughout Northern Illinois, Southern Wisconsin and Northwest Indiana. Utilizing the latest machining technology and advanced materials, we deliver complex components that challenge the limits of manufacturing. Our state-of-the-art facilities are configured for prototypes to million+ part runs and everything in between.

Contact Us

Kadon Precision Machining

Fax: 815-874-4956

5876 Sandy Hollow Rd

Rockford, IL 61109

Tel:

815-874-5850

Rockford, IL 61109

Fax: 815-874-4956

Email: info@KadonPrecision.com

Business Hours

Mon - Fri 8:00 am - 5:00 pm

Sat - Sun Closed

Kadon Precision Machining is a partner you can depend on to consistently deliver high quality precision machined parts on time, and at a fair price – Throughout Northern Illinois, Southern Wisconsin and Northwest Indiana. Utilizing the latest machining technology and advanced materials, we deliver complex components that challenge the limits of manufacturing. Our state-of-the-art facilities are configured for prototypes to million+ part runs and everything in between.

Business Hours

Mon - Fri 8:00 am - 5:00 pm

Sat - Sun Closed

Find Us

Contact Us

Kadon Precision Machining

Fax: 815-874-4956

5876 Sandy Hollow Rd

Rockford, IL 61109

Tel:

815-874-5850

Rockford, IL 61109

Fax: 815-874-4956

Email: info@KadonPrecision.com

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2024

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.